Product design & development capabilities

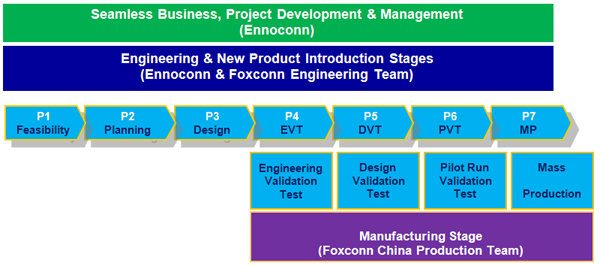

Ennoconn R&D center, located in Taiwan, has dedicated to new product/project design program. Skillful and experienced engineers elaborate from the beginning to the end with life-complete scheme (P1 to P7). Strict validation processes get your idea more practical & solid. Before mass production, our engineers will in person supervise and transfer technical know-how to production line to guarantee the quality of both design and production.

Our engineering team will support the project from the beginning until mass production for designing the product that meet customer’s expectation and ensure the manufacturing quality. Through this team work, Ennoconn can completely handle and manage the potential risk during design stage to achieve Deisgn for Manufacturing. The engineering team will be the pilot to drive the project based on:

- Layout and ID Considerations

- Component/Material Selection

- Functionality & Compatibility Test

- EMC/Safety/Enviromental Desing, Test and Debug

- Rubust Packing Design

Requirements from customers and market can be effectively implemented with the trust on our various design capability and engineering consultation. Ennoconn in-house resources benefit customers with all aspects of product conceptualization through to prototype and mass production. It may include the following services.

- Comprehensive Thermal simulation

- Power Design & Analysis

- Reliability Test

- Customized FCT Fixtures & S/W